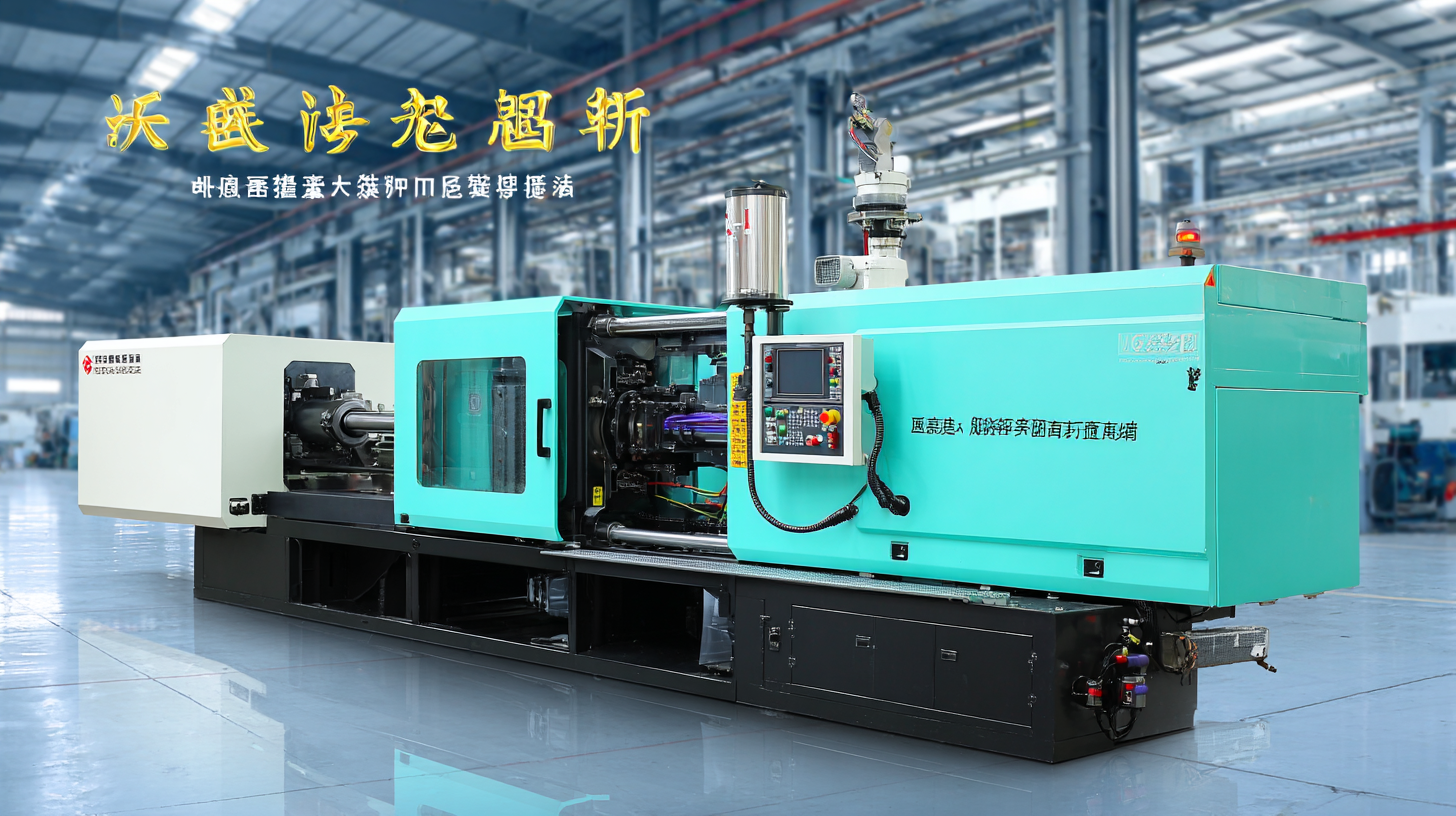

Unleashing Chinese Innovation the Best Injection Molding Machines for Global Success

In the realm of manufacturing, the significance of injection molding machines cannot be overstated, as they serve as the backbone for producing a multitude of plastic products efficiently and cost-effectively. With the rising demand for diverse consumer goods, understanding the characteristics and applications of different types of injection molding machines is crucial for businesses aiming for global success. This blog aims to explore the various types of injection molding machines available on the market, highlighting their unique features and the specific applications for which they are best suited. Additionally, we will provide insightful tips on how to choose the right injection molding machine for various product requirements, ensuring that manufacturers can leverage the full potential of Chinese innovation to enhance their production capabilities and stay competitive in the global arena.

Key Features to Look for in Top-Performing Injection Molding Machines

When selecting top-performing injection molding machines, several key features stand out as determinants of efficiency, reliability, and overall productivity. First and foremost, the machine's clamping force is crucial. A higher clamping force ensures that the mold is securely closed during the injection process, minimizing defects and allowing for intricate designs. Additionally, the injection speed and temperature control are vital parameters that influence the quality of the molded products. Machines that can rapidly adjust these settings are better suited to handle a variety of materials and production demands.

Another important aspect to consider is the machine's energy efficiency. With rising operational costs, machines equipped with servo motors or hybrid technology not only reduce power consumption but also offer enhanced precision during operation. Furthermore, ease of maintenance and accessibility of spare parts are critical for minimizing downtime and ensuring consistent production output. By focusing on these key features, manufacturers can select injection molding machines that not only meet their current needs but also support long-term innovation and growth in the competitive global market.

Key Features of Top-Performing Injection Molding Machines

This chart represents the key features and their importance ratings of top-performing injection molding machines based on industry analysis.

Understanding the Role of Chinese Innovation in Injection Molding Technology

In the rapidly evolving landscape of injection molding technology, Chinese innovation has emerged as a driving force for global success. As witnessed in the latest CHINAPLAS event, slated for April 2025 in Shenzhen, the focus on "Green + Intelligent" solutions underscores China's commitment to fostering a sustainable and smart manufacturing environment. Reports predict that the injection molding market in China will surpass $26 billion by 2025, propelled by advancements in materials and processes that enhance efficiency and reduce environmental impact.

Moreover, private enterprises in China are navigating an era of internationalization marked by their agility and innovative capabilities. These enterprises have become pivotal in promoting China’s economic globalization, particularly within the automotive sector, which is experiencing a robust growth trajectory. With the country's automotive production volume reaching nearly 25 million vehicles in 2022, manufacturers are increasingly leveraging cutting-edge technologies like digital twin applications to improve the precision and flexibility of injection molding processes. This trend not only revolutionizes production but also positions China as a key player in global supply chains, enabling businesses worldwide to harness the benefits of advanced injection molding solutions.

Comparative Analysis: Global Leaders in Injection Molding Equipment

The global landscape of injection molding equipment is rapidly evolving, with a notable surge in demand across various industries. According to a comprehensive market research study, the global rubber compound market is projected to reach USD 20.4 billion by 2033, exhibiting a CAGR of 6.5%. This growth underscores the increasing reliance on advanced injection molding technologies to cater to the rising need for customized rubber products. Similarly, the plastic injection molding machine market is estimated at USD 6.51 billion in 2023, reflecting a robust trend that highlights the importance of automation and precision in manufacturing processes.

**Tip:** Companies looking to invest in injection molding machines should prioritize equipment that offers versatility and efficiency. Upgrading to machines that utilize innovative technology can lead to significant cost savings and enhanced product quality.

Furthermore, as the automotive manufacturing sector continues to expand, the need for high-performance injection molding machines becomes even more critical. The integration of CNC technology and robotics in this space is set to revolutionize production capabilities and increase operational efficiency. With the automotive manufacturing equipment market expected to thrive, businesses must stay ahead of the curve by adopting the latest machinery designs and solutions.

**Tip:** Consider conducting a thorough market analysis and benchmarking against global leaders in injection molding to ensure your investment aligns with industry trends and demands. This approach can enhance your competitive edge and enable long-term growth.

Tips for Selecting the Right Injection Molding Machine for Your Business

When selecting the right injection molding machine for your business, it’s crucial to assess your specific production needs. Start by evaluating the types of materials you will be working with, as different machines are designed to handle varying plastic resins. Consider the machine’s clamping force, which is vital for maintaining the integrity of your product during the molding process. A machine with adjustable clamping force can provide flexibility for different projects, ensuring optimal results.

Another key factor to consider is the machine's automation capabilities. Modern injection molding machines often come with advanced technological features that enhance efficiency and precision. Look for machines equipped with user-friendly interfaces and automation options, such as robotic arms for part removal. These features not only streamline the production process but can also significantly reduce labor costs and the potential for human error. By prioritizing these aspects, you can choose an injection molding machine that not only meets your current requirements but also supports future growth and innovation in your production line.

Future Trends in Injection Molding: Innovations from China to Watch

The landscape of injection molding is rapidly evolving, and China stands at the forefront of this transformation. As the demand for precision and efficiency in manufacturing rises, Chinese innovators are developing cutting-edge technologies to enhance the injection molding process. One key trend is the integration of smart manufacturing systems. These systems utilize IoT and AI to monitor production in real-time, allowing manufacturers to optimize cycles, reduce waste, and improve product quality.

Another notable innovation is the advancement in materials science, particularly the development of bio-based and recycled materials. Chinese firms are increasingly focused on sustainability, creating injection molding solutions that minimize environmental impact while maintaining high performance. New techniques, such as multi-material molding and 3D printing integration, are also gaining traction, enabling manufacturers to produce complex and lightweight parts that meet the needs of various industries, from automotive to consumer goods. As these trends continue to emerge, they not only highlight the ingenuity of Chinese manufacturers but also pave the way for a more sustainable and efficient future in global injection molding.