What Features Define the Best High Speed Injection Molding Machine

In the realm of manufacturing, the significance of high speed injection molding machines cannot be overstated. As global demand for precision and efficiency soars, these advanced machines have emerged as pivotal tools in producing high-quality plastic components at unprecedented speeds.

According to a recent report by MarketsandMarkets, the global market for injection molding machines is projected to reach USD 22.1 billion by 2025, driven by innovations in technology and an ever-increasing need for automation.

The best high speed injection molding machines not only enhance productivity but also ensure superior dimensional accuracy, making them indispensable in various industries, including automotive, consumer goods, and medical devices.

With China positioning itself as a leader in this technology, driven by the motto "Made in China, Earn the World's Respect with Quality," understanding the defining features of these machines becomes crucial for manufacturers aiming to maintain competitive advantages in the fast-evolving market landscape.

Key Characteristics of High-Speed Injection Molding Machines: A Detailed Analysis

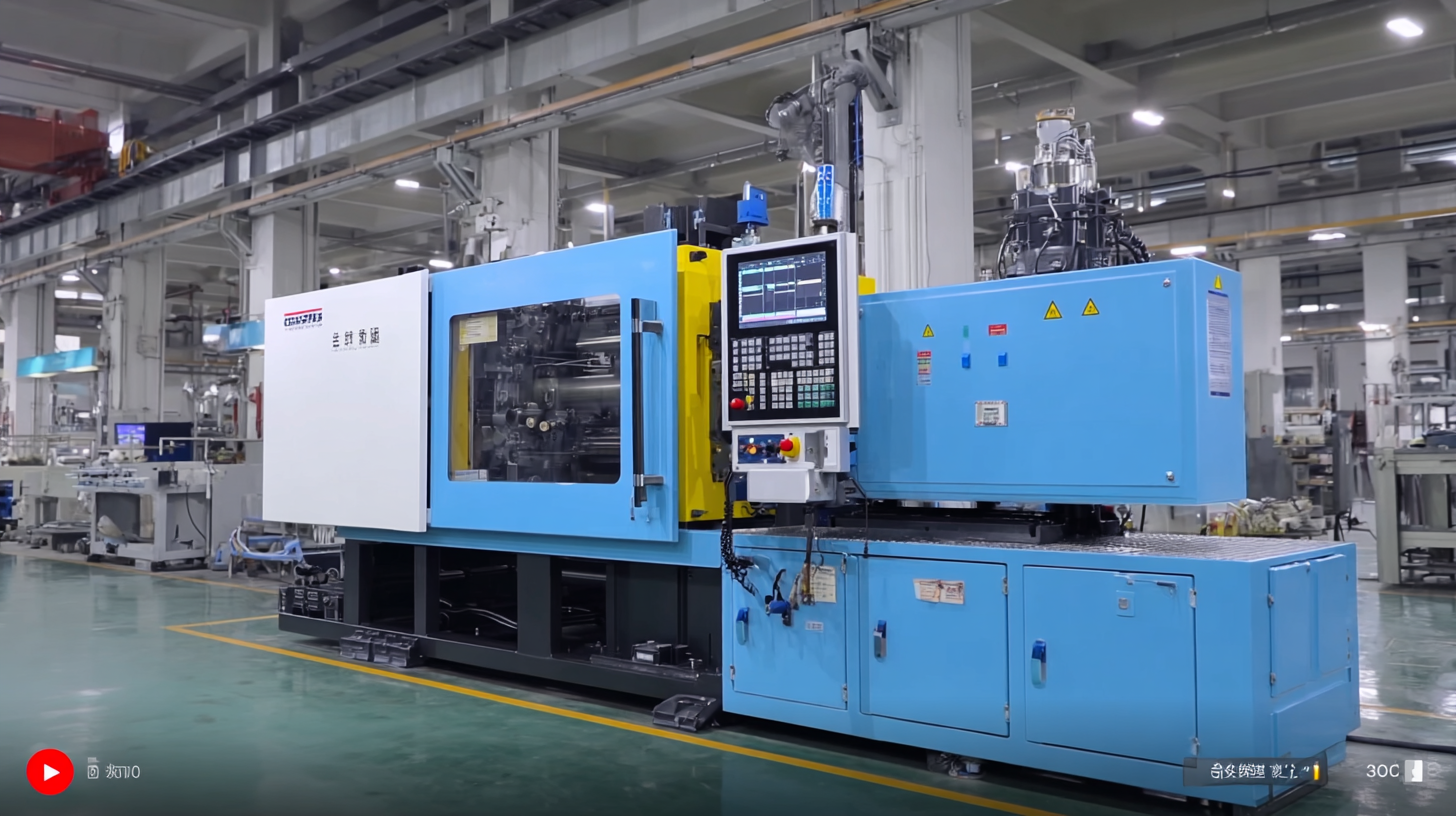

High-speed injection molding machines are becoming increasingly vital in the plastic processing industry, driven by growing demand for precision and efficiency. Key characteristics that define these machines include rapid cycle times, enhanced automation, and the ability to manage complex geometries. According to industry reports, the global plastic processing machinery market is expected to grow from $23.57 billion in 2025 to $34.62 billion by 2032, with a compound annual growth rate (CAGR) of 5.6%. This trend highlights the necessity for manufacturers to invest in high-speed injection molding technology to remain competitive.

Another critical feature of high-speed injection molding machines is their energy efficiency. Advanced models incorporate servo motors and optimized heating systems, which significantly reduce energy consumption and operational costs. As manufacturers increasingly focus on sustainability, the adoption of energy-efficient machines is projected to rise. Furthermore, the integration of Industry 4.0 technologies, such as IoT connectivity and data analytics, enables real-time monitoring and predictive maintenance, enhancing overall productivity. This combination of speed, efficiency, and smart technology positions high-speed injection molding machines at the forefront of the evolving plastic processing landscape.

Market Trends: Growth Projections for High-Speed Injection Molding Technology by 2025

The market for high-speed injection molding technology is poised for significant growth by 2025, driven by the increasing demand for lightweight and complex parts in industries such as automotive, electronics, and consumer goods. As manufacturers seek to optimize production efficiency and reduce cycle times, investing in state-of-the-art high-speed injection molding machines has become imperative. This trend is not only reshaping the way products are made but is also enhancing the quality and precision of molded components.

When choosing the best high-speed injection molding machine, consider advanced features such as servo-driven systems, energy efficiency, and quick-change mold capabilities. These features contribute to faster production speeds and reduced operational costs, making your investment more worthwhile. Additionally, look for machines with enhanced automation options, which can streamline workflows and minimize human error, ultimately increasing productivity.

As the industry continues to evolve, staying informed about emerging technologies and practices is crucial. Engage with industry experts, attend trade shows, and participate in relevant training sessions to keep up with the latest advancements in high-speed injection molding. Adapting to these changes will not only position your business for future growth but also ensure your operations remain competitive in an increasingly demanding market.

What Features Define the Best High Speed Injection Molding Machine - Market Trends: Growth Projections for High-Speed Injection Molding Technology by 2025

| Feature | Description | Market Impact | Growth Projection by 2025 |

|---|---|---|---|

| Speed | High-speed cycle times that reduce production time | Increased production efficiency, leading to cost savings | Estimated growth of 15% annually |

| Energy Efficiency | Use of advanced servo motors and energy-saving technologies | Reduction in operational costs and environmental impact | Projected market share increase by 10% |

| Precision | High accuracy in molding to minimize waste and defects | Improved product quality enhances market competitiveness | Growth in high-precision applications by 20% |

| Automation | Integration of robotics for material handling and loading | Boosts overall productivity and reduces labor costs | Expansion of automation technology by 25% |

| Smart Technology | Incorporation of IoT for real-time monitoring and adjustments | Enhanced operational insights lead to better decision-making | Increase in smart machine adoption by 30% |

Comparative Benefits: Standard vs. High-Speed Injection Molding Machines in Production Runs

When comparing standard injection molding machines with high-speed counterparts, the differences in production capabilities become strikingly clear. Standard injection molding machines excel in producing parts with complex geometries and varying wall thicknesses, making them ideal for a diverse range of applications. They offer reliable performance for medium to high-volume production but often face limitations in cycle times, which can lead to longer lead times for products.

In contrast, high-speed injection molding machines are engineered for rapid production, significantly reducing cycle times and boosting overall efficiency. These machines utilize advanced technology to optimize the injection process, allowing manufacturers to produce components faster while maintaining accuracy and quality. This is particularly beneficial in industries where time-to-market is critical, and large volumes of uniform parts are needed. By investing in high-speed machinery, companies can not only enhance productivity but also reduce operational costs over time, leading to a more competitive edge in the market.

Material Compatibility: Choosing the Right High-Speed Injection Molding Machine for Diverse Plastics

When selecting a high-speed injection molding machine, material compatibility is a critical factor to consider. Different plastics have unique properties, such as melting temperatures, viscosity, and shrinkage rates, which influence the choice of machine. A high-speed injection molding machine must be capable of processing various materials effectively, including thermoplastics, thermosetting plastics, and elastomers. Understanding the specific requirements of each material can help manufacturers achieve optimal flow, minimize defects, and maximize productivity.

Additionally, manufacturers should assess the machine's versatility in accommodating diverse plastic resin types. Some machines feature advanced technology that allows for quick changes in parameters to cater to different material characteristics. For instance, enhancing the injection speed and optimizing pressure settings can significantly improve production cycle times when working with faster solidifying plastics. Ultimately, investing in a high-speed injection molding machine that supports a broad range of materials will not only enhance operational flexibility but also enable businesses to respond swiftly to market demands.

Impact of Automation and IoT on High-Speed Injection Molding Machine Efficiency and Output

The rise of automation and the Internet of Things (IoT) has significantly transformed the landscape of high-speed injection molding machines. These advanced technologies enhance efficiency by streamlining various processes. Automation minimizes human intervention, resulting in faster production cycles while maintaining consistent quality. The integration of robotic arms and automated loading systems allows for seamless material handling, reducing downtime and optimizing workflow.

Moreover, IoT plays a crucial role in elevating the performance of high-speed injection molding machines. By connecting devices to the internet, manufacturers can monitor real-time data related to machine performance, production speed, and possible malfunctions. This connectivity enables predictive maintenance, allowing operators to address issues before they escalate. As a result, manufacturers can achieve higher output levels while reducing waste and energy consumption. Embracing these technological advancements is key to staying competitive in an increasingly demanding market.