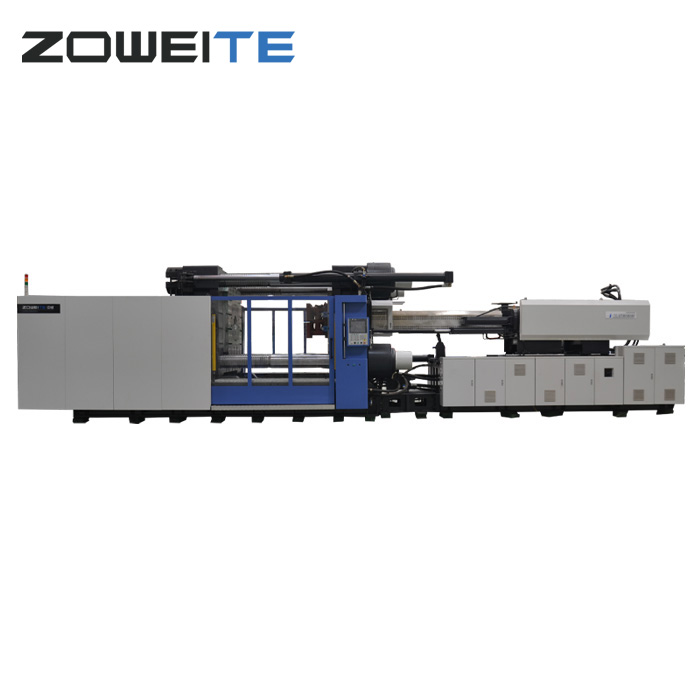

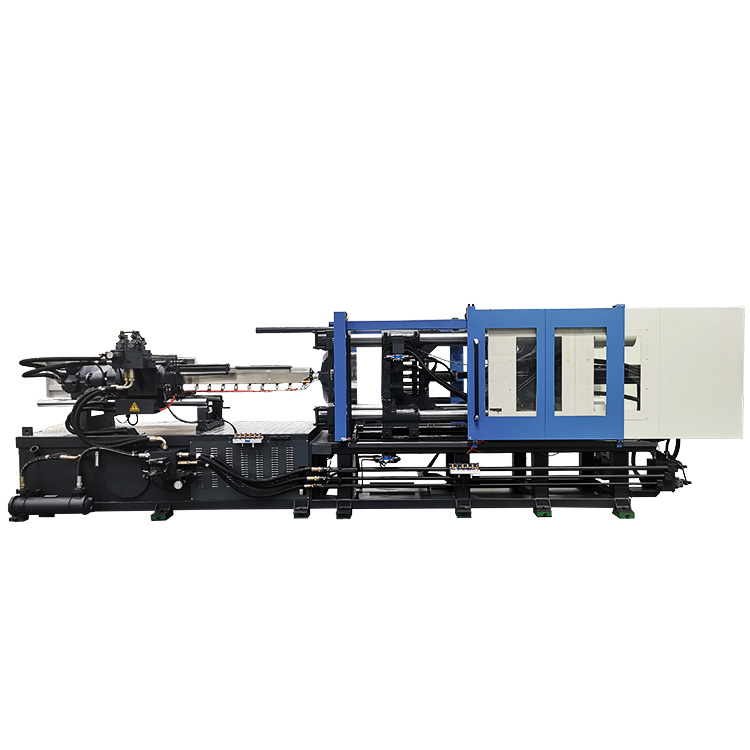

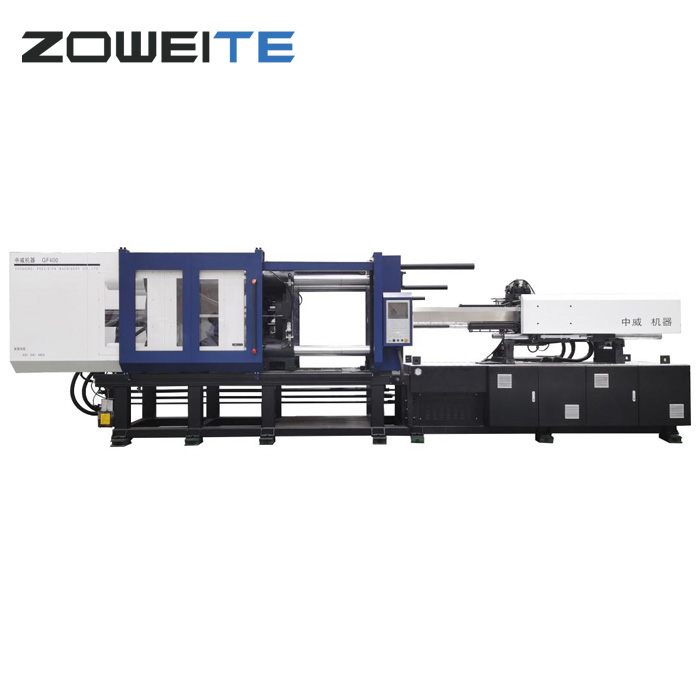

Efficient and durable Lens lamp injection molding machine Manufacturers

To consistently enhance the management method by virtue of the rule of ""sincerely, fantastic religion and top quality are the base of business development"", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for Efficient and durable Lens lamp injection molding machine,Lens linjection molding machine,Low failure rate Lens lamp injection molding machine,Easy maintenance Lens lamp injection molding machine,Auto parts Lens lamp injection molding machine, Now we now have established steady and lengthy company associations with clients from North America, Western Europe, Africa, South America, extra than 60 countries and regions.

Efficient and durable Lens lamp injection molding machine, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality items and good after-sales services. Up to now, our solutions have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Hot Products

Pet Preform Making Machine

GIT® PET preform making machine made in China is used to produce various plastic preforms. At present, PET is widely used in the container packaging of beverages, purified water, candy, biscuits, edible oil, cosmetics, pharmaceuticals and cleaning products. With the popularity of bottled drinks, the two-step forming process is used in the forming of large-volume tube blanks. The advantages are full.Plastic Bucket Injection Molding Machine

The manufacture of all plastic containers involves injection molding machine. Many buckets are made out of high-density polyethylene. HDPE is a durable, non-reactive thermoplastic that resists impact and inhospitable climates during transit or storage. In the GIT® plastic bucket injection molding machine process, raw HDPE resin, which in the beginning of the molding process is called stock, is loaded into a hopper. The hopper then directs the stock into a conveyance channel where a large screw forces the stock toward a mold. As the screw turns, the combination of friction and pressure heats the stock.Fruit and Vegetable Basket Injection Molding Machine

The Fruit and Vegetable Basket Injection Molding Machine is a special model of disposable plastic fruit basket production equipment developed by our company according to the characteristics of the fruit and vegetable basket.GIT® GF400K, GF530K and other injection molding machine are specially developed by GIT® for fruit and vegetable basket.Pvc Pipe Fitting Injection Molding Machine

GIT® PVC pipe fitting injection molding machine made in China is a machine for producing pipe fittings of various shapes,A pipe fitting is a part that connects a pipe into a pipe run.Plastic Paint Bucket Injection Molding Machine

Plastic oil drum injection molding machine is a machine used to produce paint drums and oil drums in daily life. GIT® Injection Molding Machine launched a special machine for the production of paint buckets-plastic paint bucket injection molding machine from China factory. It has two models: GF650CEH and GF780CEH. The parameter table is shown in the figure below:120 tons injection molding machine

GIT® 120 tons injection molding machine is a small injection molding machine with small floor area. It is suitable for producing all kinds of small plastic parts, such as plastic caps, nylon cable ties, etc. GIT® 120 tons injection molding machine has servo machine and standard injection molding machine. GIT manufacturer can also provide the suitable machine and best offer according client’s requirements.