Vertical Injection Machine Manufacturers

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Vertical Injection Machine,Plastic spoons injection machine,Plastic Spoons Injection Machine,Injection Machine Plastic Spoons,Plastic Injection Molding Machine, Accurate process devices, Advanced Injection Molding Equipment, Equipment assembly line, labs and software growth are our distinguishing feature.

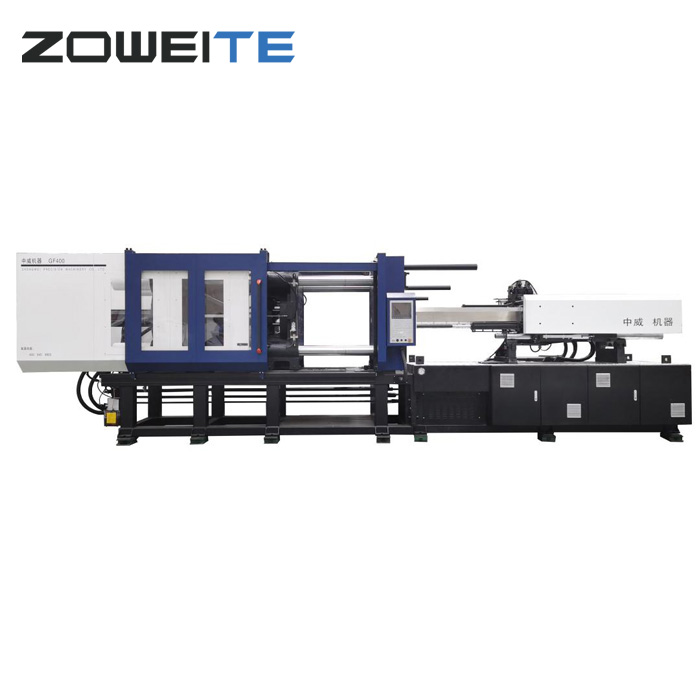

Vertical Injection Machine, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we offer, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and comprehensive parameters and any other info weil be sent for you timely for the inquiries. So remember to get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we're likely to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Hot Products

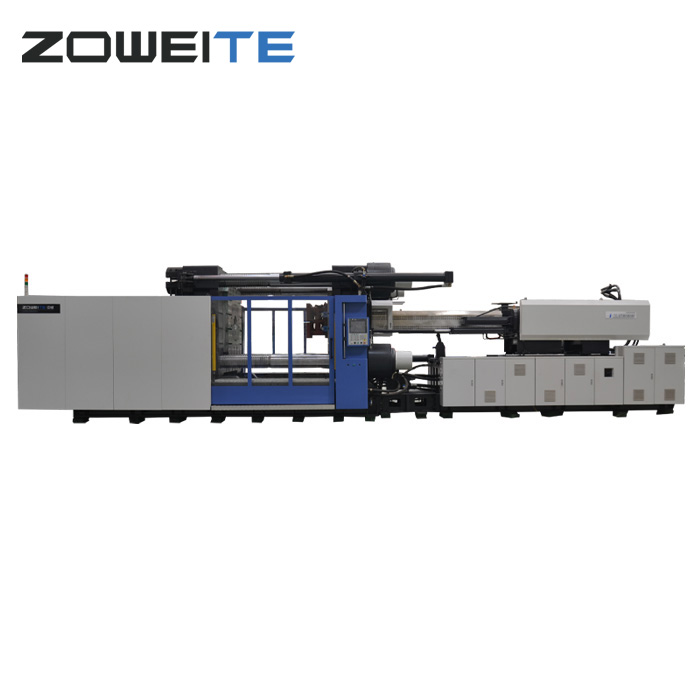

PET preform for water bottle injection molding machine

PET preforms come in various sizes and neck finishes to adapt to different bottle designs and applications. GIT® can customize PET preform for water bottle injection molding machine according to customer requirements.High Speed Plastic Making Machine

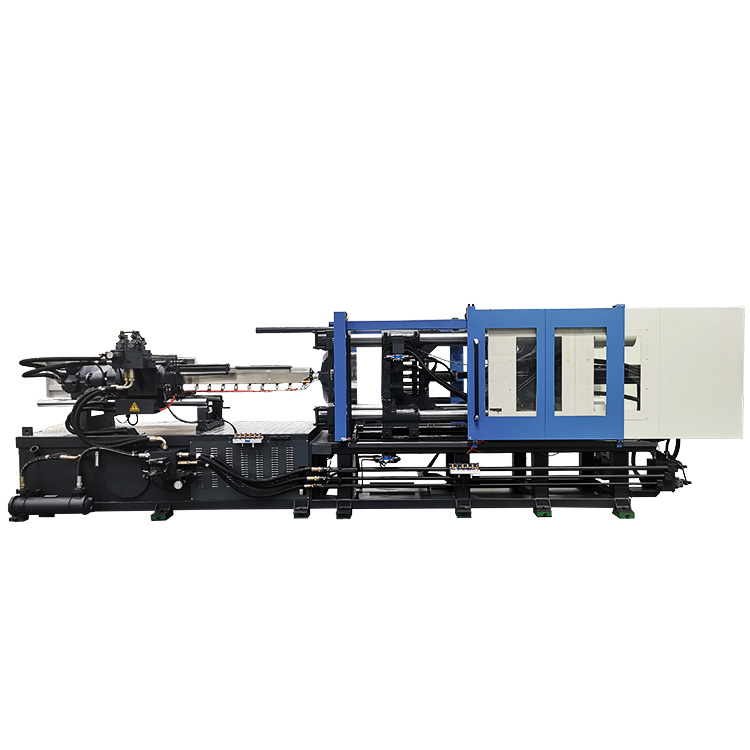

GIT® High speed plastic making machine can also be calling high speed injection molding machine or high speed injection machine. Tianjin Yihe GIT (GIT) Precision Machinery Co., Ltd is a high-tech enterprise specialized in designing, manufacturing and selling various types of high-precision, energy saving, stable performance injection molding machines in China.Cable Tie Injection Molding Machine

Plastic tie is made of GIT® cable tie injection molding machine in China. In its manufacturing process, it is extruded through cable tie injection molding machinemold, and then the shape of the molded product presents a narrow strip. The main application fields of tie are very wide, including automobile industry, electronic industry, electrical industry, industrial field, manufacturing field and other industries. It plays the role of binding, tightening or arranging wires in places.Plastic Crate Injection Molding Machine

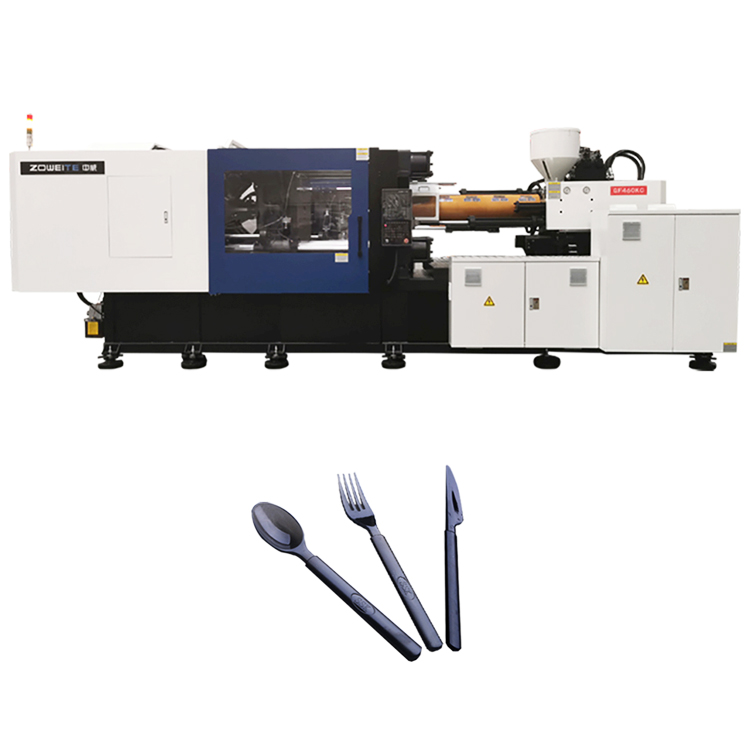

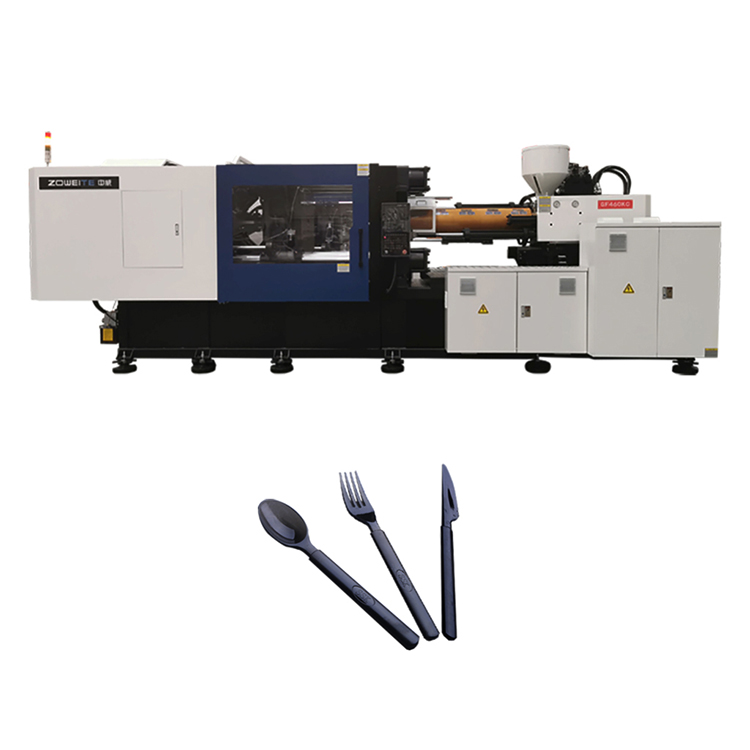

Plastic crates are manufactured through a process called plastic injection molding. An GIT® plastic crate injection molding machine mold made in China is a machine that takes raw plastic product, or stock, and processes it into a usable product. plastic crate injection molding machine molders begin with a collection of stock in a hopper which is directed into a conveyance channel. A screw will turn in the conveyance channel which combined with heating, helps to liquefy the plastic in preparation for the mold.Disposable Tableware Injection Moulding Machine

GIT® factory is disposable tableware injection moulding machine manufacturer and supplier. Plastic tableware is becoming more and more popular in our daily life.Cap Molding Machine

GIT® Cap molding machine in China is a machine used to produce plastic bottle caps. What is the essential performance of a high-quality bottle cap? It is undoubtedly hermeticity and safety. Need to consider easy opening, weather resistance and impact resistance. Nowadays, consumers' requirements for packaging are constantly increasing, and the Chinese market has higher and higher requirements for the accuracy, efficiency, stability and flexibility of the equipment for producing cap molding machines.